Development

Charging Ahead !!DEVELOPMENT

C4V’s core DNA is based on our never ending pursuit of sustainable solutions and our start as a Lithium-ion Battery Technology company on the leading edge of Innovation. If one of our existing solutions don’t work for you, we will design a solution that will!

Our people are driven by a challenge and relish the opportunity to work on real world problems and come up with scalable and cost effective solutions.

C4V has worked with Premium Automobile manufacturers, Tier 1 automotive suppliers, Formula 1 racing teams, the US Departments of Defense and Energy plus a myriad of others as we flex our R&D muscles leveraging years of experience to design solutions that work.

What do custom cell designs address?

Cell form factors

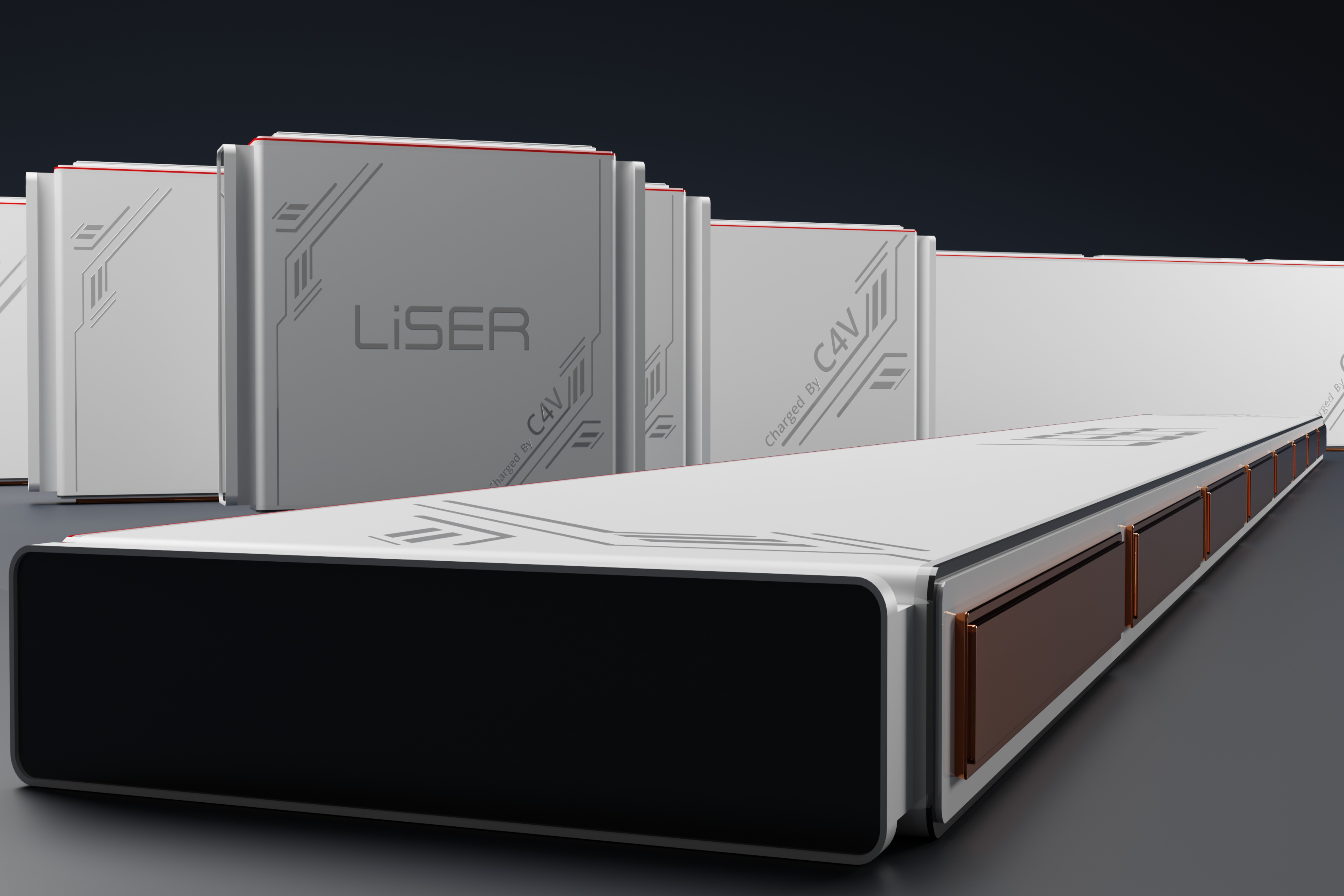

We believe that the Prismatic form factor will withstand the test of time due to ruggedness and manufacturability but, C4V has deep experience working with cylindrical cells and still creates coin and pouch cells on our pilot lines at the C4V labs. Typically, clients come to us with a given form factor.

Cell Chemistry

We use our existing chemistries, which covers most of the current options most recognized by the industry, and begin the process of iterating the recipes to achieve the desired battery performance. Anode, Cathode and Electrolyte are all in play and we don’t give up easily knowing that the right combination of materials will yield the needed result.

Thermal Issues

The heat generated by the chemical reaction within the cell is a constant variable that directly influences the battery performance and the safety of the user. We are highly aware that a battery induced fire can be catastrophic. Safety is priority #1 (sustainability being #1A) and C4V’s experience mitigating thermal runaway issues is significant. Of course it helps that our P Series Tech (Phosphate based) is oxygen deficient and does not create the environment for thermal runaway but, our N Series chemistry also undergoes our patented Bio-Mineralization process making a thermal event much less likely to happen.